Increase Efficiency with Dexion High-Density Shuttle Systems

Dexion Auto Shuttle Systems represent the pinnacle of high-density pallet storage technology. Designed for maximum efficiency and flexibility, these systems optimize warehouse space utilization while enhancing productivity and safety in your logistics operations.

Key Features of Dexion Auto Shuttle Systems

Automated pallet handling for increased efficiency

High-density storage maximizing warehouse space

Flexible design adapting to changing storage needs

Enhanced safety with reduced manual handling

Improved inventory control and management

Your business:

You have a low SKU count and large batches of raw materials or finished goods. Stock can be either highly active or static, but storage density is a major feature you require. You typically dispatch by batch and use either First In First Out or Last In First Out.

Our solution:

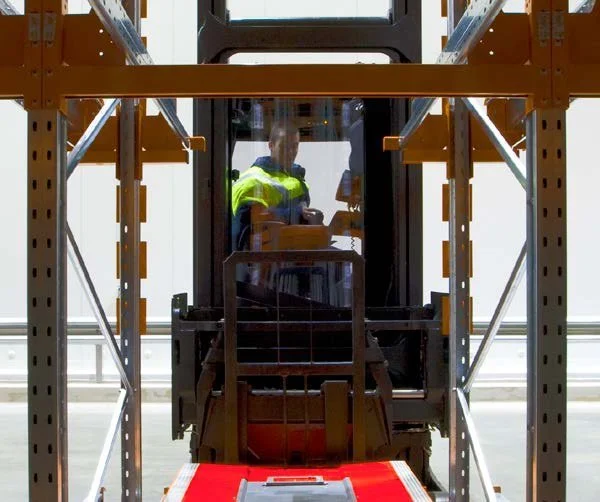

The Dexion Auto Shuttle systems offers high-density pallet storage without the use of forklifts. It makes the most of limited space and forklift truck fleets. The Auto Shuttle unit deposits and retrieves pallets within the system. A Shuttle solution is applicable for ‘pack and hold’ operations where pre-picking and staging is possible, ‘dock split’ and ‘hold’ operations, and the staging of outbound pallets by route or truckloads in lieu of conventional floor staging.

Shuttle stock back & forth

The Auto Shuttle unit travels below the pallets then elevates the pallet from the support rails and carries it back and forth within the system as required.

The Auto Shuttle unit is mechanically propelled ensuring high reliability and low energy consumption.

Full access high density

Best in breed equipment, patented mechanical lifting motion, means no hydraulics and few moving parts, ensuring low noise during operations. If an error is detected, the Auto Shuttle unit will return to the home position for easy retrieval and repair.

Positions pallets perfectly

Lead in guides act as a visual and physical aid for the forklift operator to assist with the placing of the Auto Shuttle unit and pallets.

Control via handheld remote

At your fingertips

Scanning with RF device, the screen tells the operator the destination of the pallet within the rack. The Auto Shuttle unit is controlled via the hand held remote.

High density with operational safety.

The rails support and guide the Auto Shuttle in operation. The rails provide detection holes which are aligned with the satellite unit sensors for shuttle unit operation. High tolerance rail joints allow for smooth running of the Auto Shuttle unit in deeper storage applications.